We specialize in precision cleaning and lubrication of bearings for high-reliability aerospace applications. Our facility is equipped to efficiently process small custom jobs and/or up-screen commercial off-the-shelf (COTS) bearings, delivering enhanced reliability and longevity for demanding deep space environments.

As part of the COTS up-screen procedure, Mr. Halpin performs a 100% visual inspection at ≥10X magnification on each bearing in the batch. He carefully examines for the following potential defects:

This image, captured by the microscope’s mounted camera, provides a representation of Mr. Halpin’s inspection perspective. However, his actual view is even more precise, as he observes the details through each eye separately, enhancing depth perception.

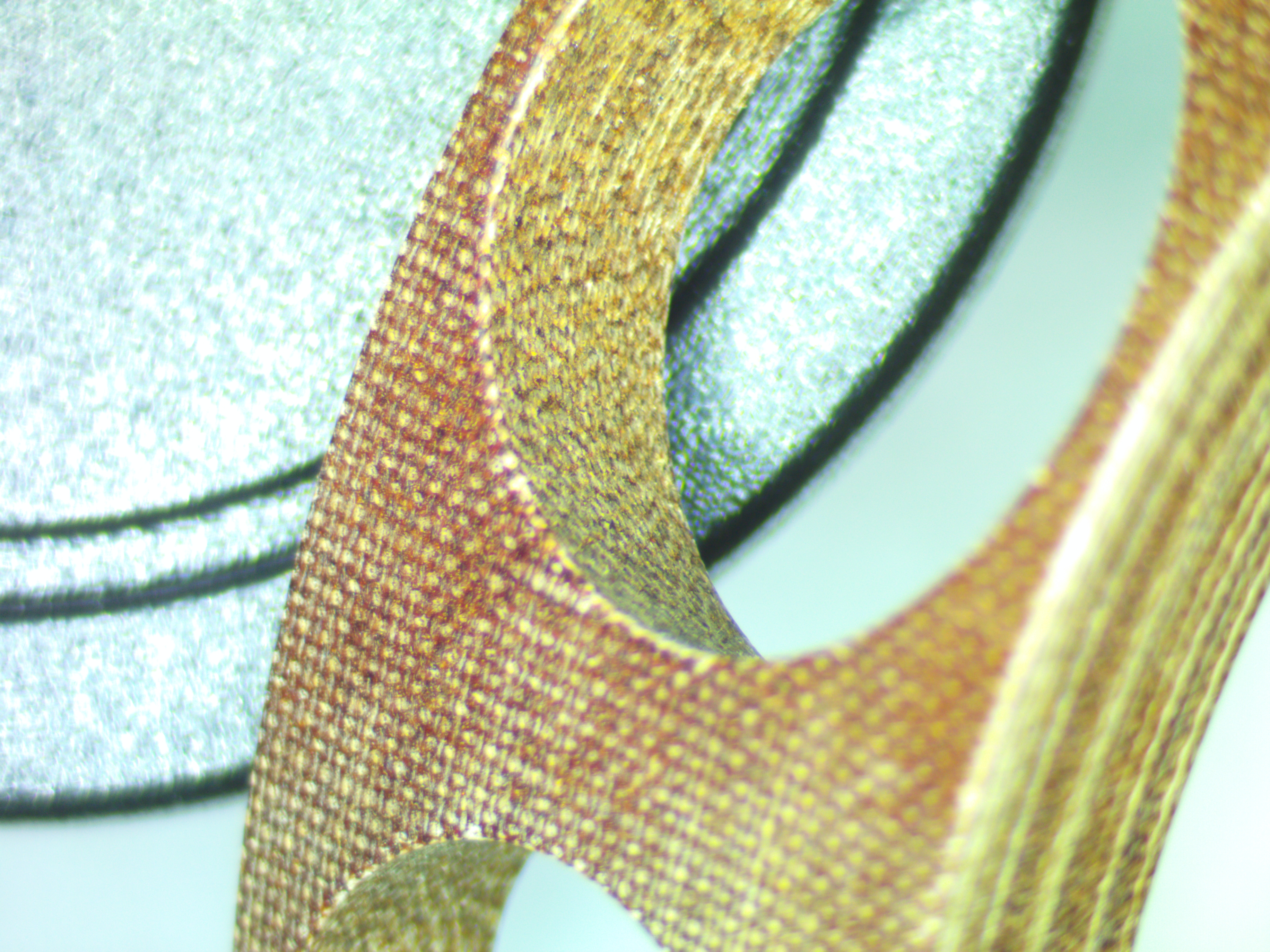

This photograph showcases a ball pocket on a cleaned and dried phenolic cage, where the cotton layers are clearly visible, highlighting material structure and cleanliness.

This image showcases a cleaned and dried bearing assembly that is prepared for vacuum oil impregnation. Inspecting the bearing at this stage allows any imperfections to be identified before final processing, maintaining high-reliability standards. Furthermore, inspection is more effective than after oil impregnation, as the presence of oil distorts light under the microscope, making fine surface details harder to detect.

This bearing has undergone vacuum oil impregnation. The focal plane of this image is set on the oil meniscus at the outer raceway contact, highlighting its formation at the top of the ball.

Each ball-to-raceway contact should exhibit a consistent meniscus, fully surrounding the contact point. As the bearing rotates, the meniscus should track the contact points, ensuring uniform lubrication on all contacting surfaces. Additionally, there should be no evidence of de-wetting, as any disruption in the meniscus could indicate improper oil adhesion, which is a sign of surface contamination.

This image captures a batch of bearings undergoing processing in the vacuum oven. The white cylinders are impregnation chambers, pre-filled with oil, ensuring the oil is de-gassed prior to bearing insertion.

The dry-out process is especially critical for bearings with phenolic cages, as it directly impacts oil retention efficiency. Mr. Halpin has developed procedures for this process that are backed by experimental testing, ensuring optimal performance and reliability.

Mr. Halpin is meticulously applying grease to a batch of bearings, ensuring consistent lubrication for optimal performance. Each bearing is filled with a specific quantity of grease, verified through pre- and post-weight measurements to milligram accuracy.

This rigorous process maintains consistent lubrication levels, enhancing reliability and providing accurate tracking for quality assurance.

These bearings have undergone precision cleaning, detailed optical inspection, vacuum oil impregnation, and grease filling. Next, they will undergo grease run-in, stabilizing lubrication distribution before double-bag sealing for secure shipping.

This meticulous process maintains high-quality standards, preparing bearings for demanding aerospace applications.

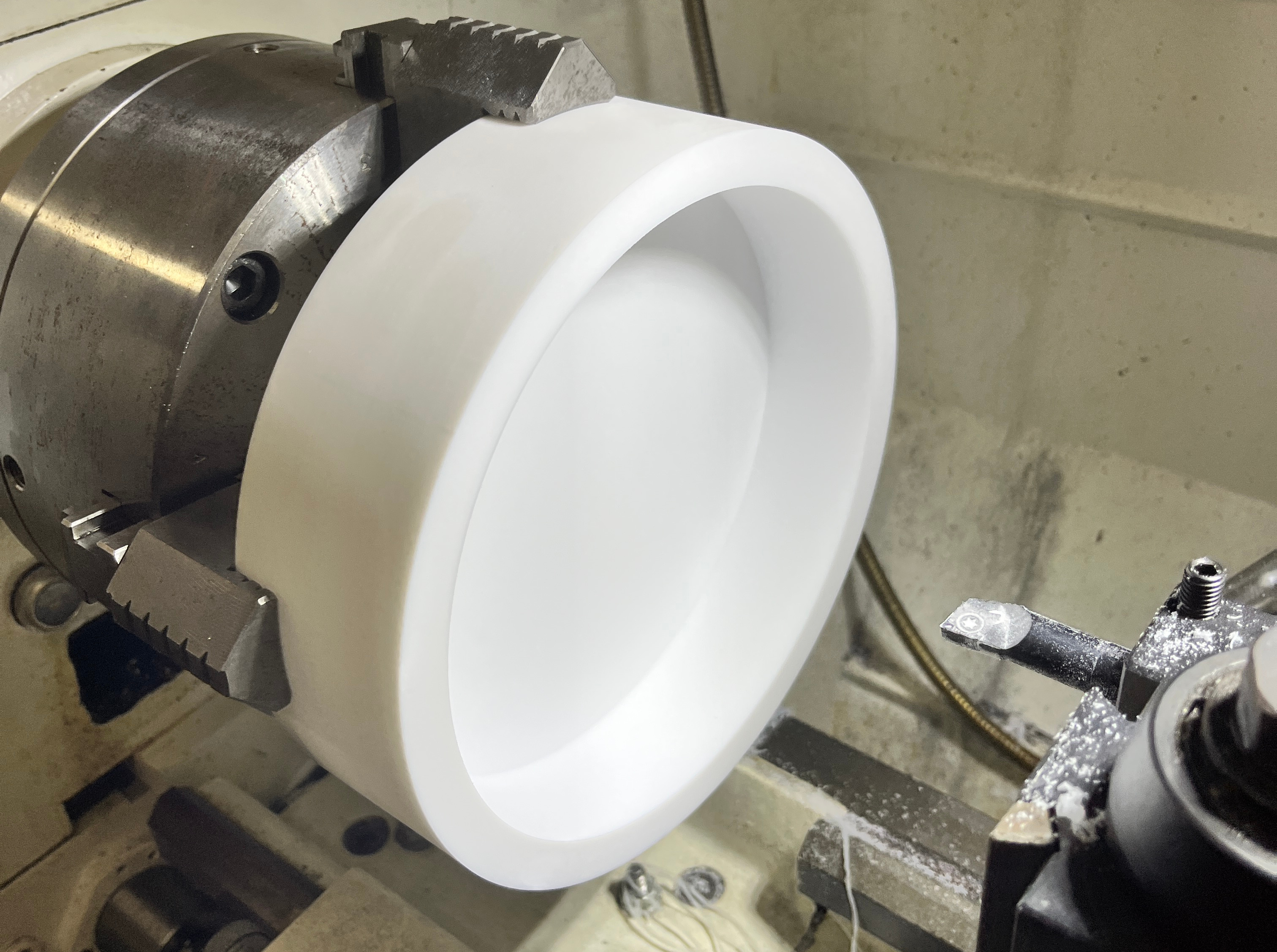

This image captures a lubrication chamber being manufactured on our engine lathe, demonstrating our in-house machining capabilities. We produce custom tooling and fixtures as needed, ensuring rapid turnaround for our customers.

Our facility is equipped with a 3-Axis milling machine, engine lathe (as shown), 3D printer, band saw, hydraulic press, and grinding wheel, providing a versatile range of machining options. We also have a precision granite surface for various dimensional inspections.

This image showcases custom fixturing designed for a batch of bearings, optimizing the oil impregnation process for efficiency and cost savings. The impregnation chambers are specifically engineered to minimize the net volume of oil covering the bearings, reducing material costs without compromising lubrication quality.

In this setup, the suspension rod heights have been adjusted to position the bearing stack above the oil level during the draining step, ensuring controlled impregnation and proper excess oil removal.

This video shows a chamber containing two differently sized nested bearings undergoing vacuum impregnation with Pennzane 2001 oil. The large air bubbling observed is likely caused by trapped air pockets formed during submersion in the oil chamber.

Additionally, the cotton-phenolic bearing cages inherently contain absorbed air, which will be extracted through the vacuum process, ensuring thorough impregnation and optimal lubrication retention.

These small parts are composed of porous sintered iron, undergoing vacuum impregnation with Brayco 815Z oil. As the process removes trapped air, you can observe air escaping from the pores, forming bubbles that rise to the surface.

For clearer visualization, the video speed has been increased to 3X, allowing rapid observation of the air extraction phase and subsequent oil absorption into the material’s structure.