Engineering Excellence at Every Level - Consulting, Software, Training, and Clean & Lube Processing.

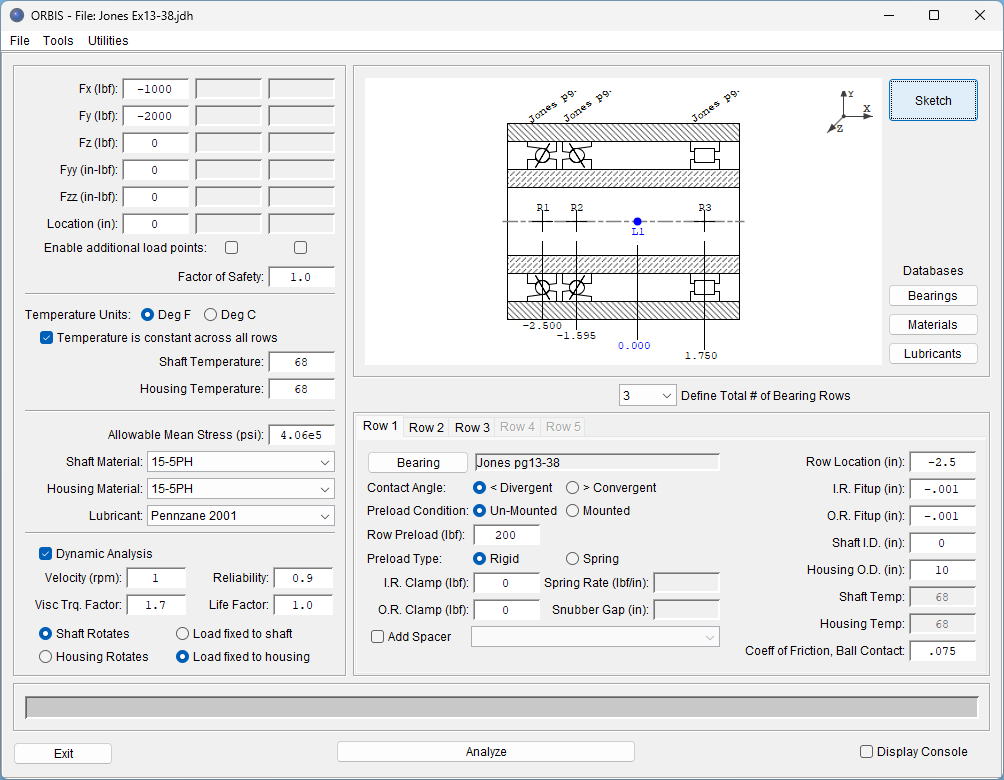

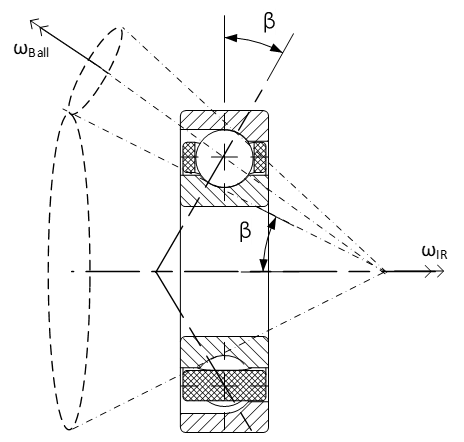

ORBIS is a proven computational tool designed to solve the nonlinear elastic behavior of rolling-element bearing systems. Trusted in the aerospace industry for nearly two decades, ORBIS has established itself as the go-to solution for precise and reliable rolling-element bearing analysis.

Learn more about ORBIS.

We also specialize in precision cleaning and lubrication of bearings for high-reliability aerospace applications. Our class 10K clean room facility is equipped to efficiently process small custom jobs and/or up-screen commercial off-the-shelf (COTS) bearings, delivering enhanced reliability and longevity for demanding deep space environments.

See Bearing Processing for further details.

Rolling-element bearings are crucial in mechanical systems, and mechanical engineers should have a solid understanding of them. Here's five key reasons why:

Learn more about our training options.

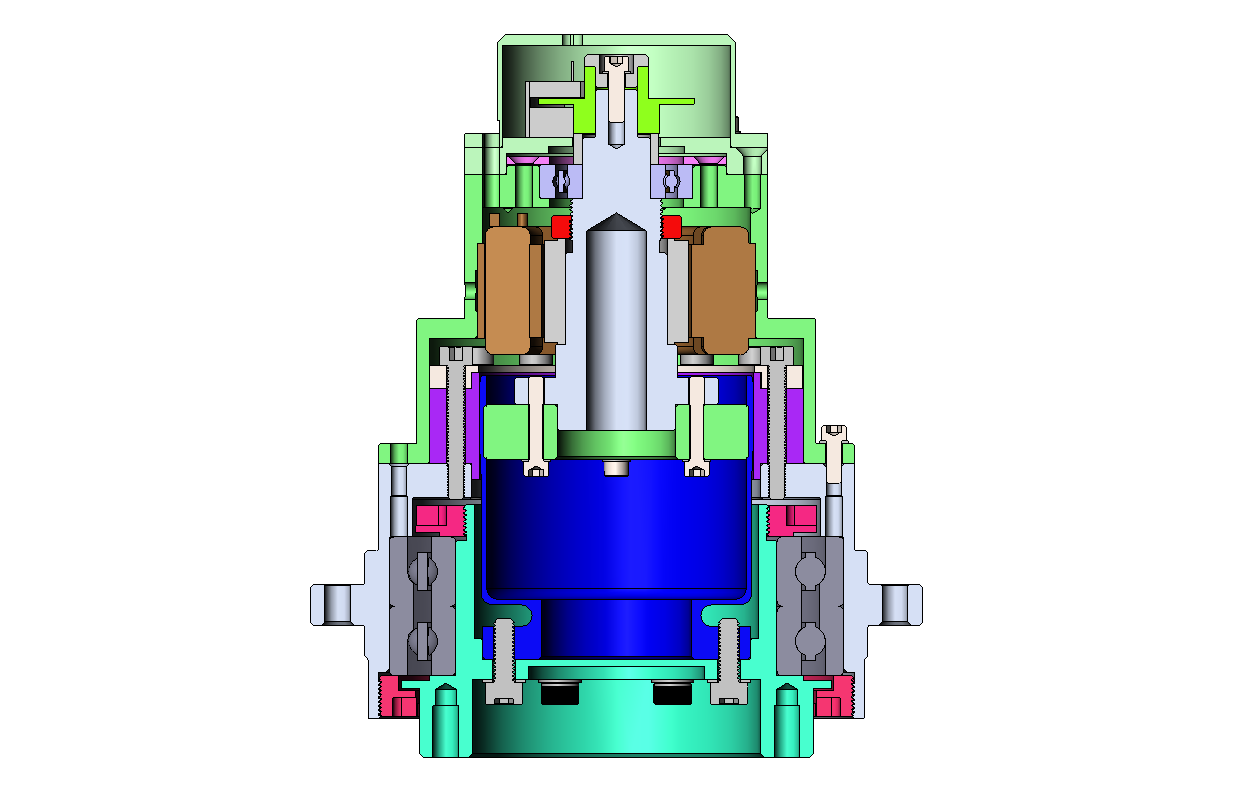

With more than 20 years of hands-on experience, Mr. Halpin has played a key role in developing space-qualified mechanical systems, including precision pointing and tracking gimbals, actuators, deployment devices, and advanced mechanisms. Since 2001, his contributions have resulted in over 1,000 lbs of on-orbit hardware, providing innovative solutions that enhance aerospace capabilities.